Materials & process

Materials & process

What makes our quality?

We are part of a slowly dying community of artisans that are truly driven by a passion for the craft; we don’t take any shortcuts when it comes to creating our products, neither do we sabotage long lasting quality for quick money. We strive to maintain a thoroughly fair trade family business focused on durable goods created in small, limited edition batches. Why so?

Because when crafting a bag or belt by hand, we spend countless hours bent at the work bench, investing our time, sweat & sometimes quite literally, our blood in every piece we create. Thus, to pour our hearts and souls into anything other than the best quality we can achieve, is a waste. We choose the best materials to accompany our craftsmanship in achieving long lasting products that can be used for a lifetime, then passed on as heirloom pieces.

That is why our products are endowed with our Lifetime Guarantee.

To give an example:

In most department stores one can find a wallet with 10 card slots, 3 cash pockets, a coin pouch and an ID slot, with the words "genuine leather" or "real leather" embossed on it, at less than $50. That makes one wonder why a hand crafted leather wallet with a much more minimalist design and fewer pockets is labelled with a much higher price tag. That is because the grade of leather used and the craftsmanship employed in crafting such a wallet is far superior; no artisan wants to waste their time on cheap materials. Also, artisans tend to keep the designs simple and functional, to minimize the cost of time. Thus, the brands that use cheap, low quality leather and underpaid workers in 3rd world countries will always have a lower price, but the quality of hand crafted vs mass-produced is paramount.

As Benjamin Franklin wisely said, "The bitterness of poor quality remains long after the sweetness of low price is forgotten."

Read more about the materials we use and the process each piece of leather goes through before turning into a unique leather product.

MATERIALS AND PROCESS:

Cutting & assembly

We receive our leather in whole hides, which we cut by hand as we work through the list of orders. Our items are created on request, to ensure no item is buried in a drawer awaiting to be purchased.

We cut, shape and mark each piece of leather by hand, then proceed to prepare the edges for stitching, when applicable. We punch all the holes by hand using fork-like leather hole punches.

We stitch each item by hand using the saddle stitch technique. (See below why this is so important).

The last step in the making process is burnishing the edges using a special agent called gum tragacanth. In some cases we paint the edges, to create a contrast, yet we always use water based dyes, to subtly reveal the layers of the leather stitched together.

Other items do not require stitching, in which case we attach durable hardware that does not rust.

Saddle stitch

All of our goods are stitched by hand using the saddle stitching technique. Why should you care about that?

Because the difference between machine lock-stitch and saddle stitch is crucial when it comes to product durability.

It’s true that machine-stitched goods are made much faster and thus are much cheaper, but as said above, the compromise on the quality is not worth the bucks you’re ‘saving’.

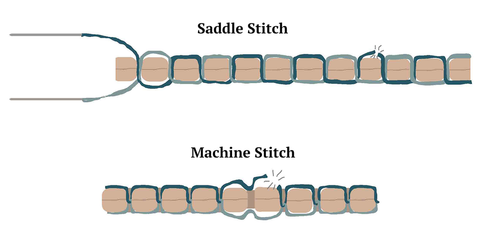

As you can see in this illustration (credits to Rivet & Chain):

In machine stitching, there are 2 different threads that go through the hole, meet between the layers of leather, get inter-locked, then return through the same hole. That creates a major stress point in the seam line, since both these threads are constantly trying to cut each other, until one thread snaps. When that happens, both of them unravel and the whole stitching is loose in no time.

On a wallet, for example, this usually happens at the folds next to the card slots, where the pressure resulted from repeated open-close movements cause the thread to break.

There’s a completely different story when it comes to saddle stitch. Used for centuries by saddle makers, this sewing technique has proved its worth in all the horse saddles that resist for decades throughout all the exposure to water and sun, as well as extreme pressure. If horses can’t pull these stitches open, what can?

When stitching saddle-style, we push the long thread in through a hole, pull it out through the next, creating an overlapping pattern along the stitch line. When reaching the end, we don’t cut the threads; we return on the same stitches, at least 3-4 holes, then cut and burn the ends of the thread to make sure the stitching stands no chance of ever coming undone. If an Anarchist stitching rises among the durable stitches we create, and dares to unravel, then our Workmanship guarantee has got your back.

Thread

We use thick, three-strand cotton and polyester thread covered in wax. The thickness gives it strength, and the wax coating makes it immune to water damage and exposure to elements.

We use mainly full grain, vegetable tanned leather sourced from European countries (France, Italy and United Kingdom). Since in some cases we’re unable to source a particular color, texture & thickness combination among the vegetable tanned options, we use chrome tanned leather imbued with oils and waxes for extreme durability and water-resistance. Our favourite leather choice comes form the world-famous, US based Horween tannery. The Horween leather range has a rich texture and a wonderful pull-up effect.

Regardless of the tanning methods, we guarantee to only use full grain leather in making any of our products. Ask any leather artisans and they will tell you that full grain leather is the best leather money can buy. We’ll explain below why.

1st, let’s make clear what VEGETABLE TANNED LEATHER is:

The full grain, non-branded, stamped or split, all natural hides are turned from animal hides into leather during the tanning process. In the case of veg tan leather, this process takes weeks to months, and the coloring agents are naturally occurring oak bark and plants tannin. This is the most environmentally-friendly tanning method, hence our choice as main material.

This type of leather evolves with the use of the product, developing a unique patina on each item.The goods made using veg tan leather look better with age, compared to the bags you get in high street shops, that never look as great as in the day you bought them.

FULL GRAIN LEATHER is the top layer of the hide that contains ALL of the grain, hence the name. It is the most durable types of leather, regardless of the animal of provenience. Combining full grain leather with veg tan method results in a product that lives for decades, while aging graciously. The veg tan, full grain leather celebrates each unique character of the hide that pay tribute to the life of the animal (bug bites, scars, stretch marks), thus each product is absolutely unique.

TOP GRAIN LEATHER is deceiving in that it mimics full grain leather, but it’s secondary in quality. This leather is resulted from splitting the top layer of the hide. It is then sanded and refinished to hide all the unique characters, and as a result, the strong fibers form the top are removed. Resulted is a leather that does not age well, and has its durability removed during the sanding process.

GENUINE LEATHER is what’s left after the top grain leather is made: the bottom layer of a hide. It is then treated and sprayed to resemble full grain leather, but it’s by far less durable.

This is the most common type of leather on the market and is used by major retailers and designers. Most wallets, bags and belts found in department stores are made using this type of leather, since it’s one of the cheapest and it presents no character, thus the mass-produced products resulted look exactly the same. Despite being made from ‘real leather’, as they make you believe, the products break quickly and don’t age nicely.

BONDED LEATHER is garbage. Literally. It is made from all the shavings and scraps resulted from the making of top grain or genuine leather. These left-overs are bonded together with glue, then the ‘leather’ is re-surfaced to have a nice appearance. This junk is then passed on as ‘real leather’ by retailers who, quite frankly, don’t give a damn about the quality.

It’s cheap, falls apart rapidly and it’s the evil of the leather world that no-one speaks about.

OUR HARDWARE

The metal parts we use for belts, bags, dog collars and other carry goods, such as: buckles, Chicago screws, rivets, clasps and studs are made from solid brass, stainless steel or copper.

These materials do not rust and provide extreme durability throughout wear and exposure to elements.

Exceptions:

Some of the bolts used for leather pulls might contain alloy metals, but that does not affect the strength and durability of the products.

Please refer to individual listings for details on specific materials used.

If you have any questions regarding how we craft our leather goods, please contact us at hello@minustudio.co

Curious to know our steps toward sustainability?

Check our Sustainability Statement here.